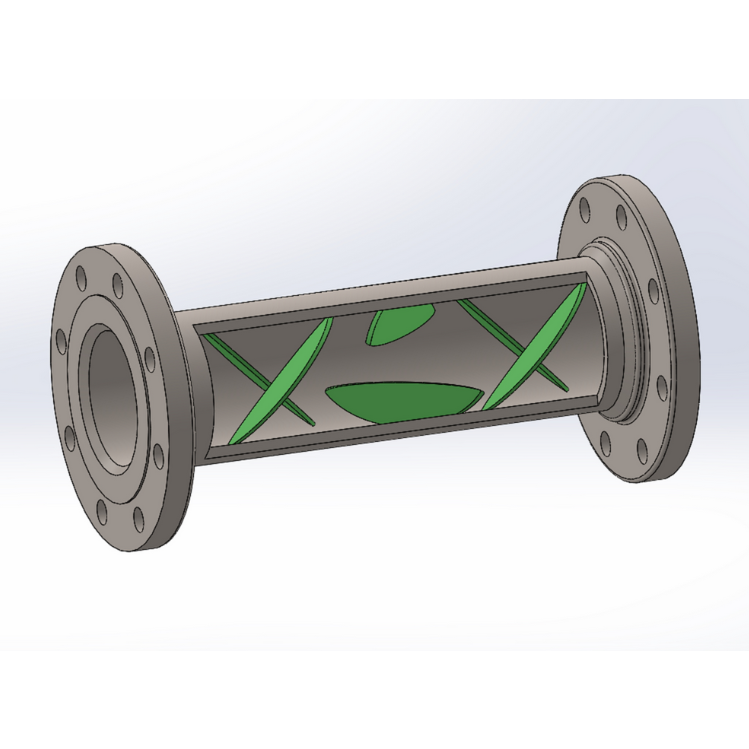

Description

MXR static mixers provide superior performance in the blending of chemical and petrochemical products. The type L-PD mixer provides a non-clogging design with a low pressure drop.

Features & Benefits

- Low Pressure Drop & High Mixing Efficiency

- Roughly 65% lower than conventional static mixers

- High efficiency for liquid-liquid, liquid-gas, & gas-gas mixing

- Non-Fouling Design

- Resistant to fouling or clogging due to open design

- Self-cleaning

- Allows objects up to one half the nominal diameter to pass

- Mixing Action

- Excellent wall-to-wall radial transfer

- Intensive contact due to momentum reversal and flow impingement

- Short Mixing Length

- Typical length required is just 2 to 4 times the nominal pipe diameter

- Optional Injector

- Better dispersion and distribution of additives prior to mixer

- More efficient mixing

- Materials of Construction

- Carbon steel, stainless steel, titanium, and other exotic metals

- FRP, PVC, CPVC, PVDF, and other thermoplastics

- Typical Applications

- Water treatment: Mixing additives

- Power Plants: Introducing and mixing gaseous additives