Description

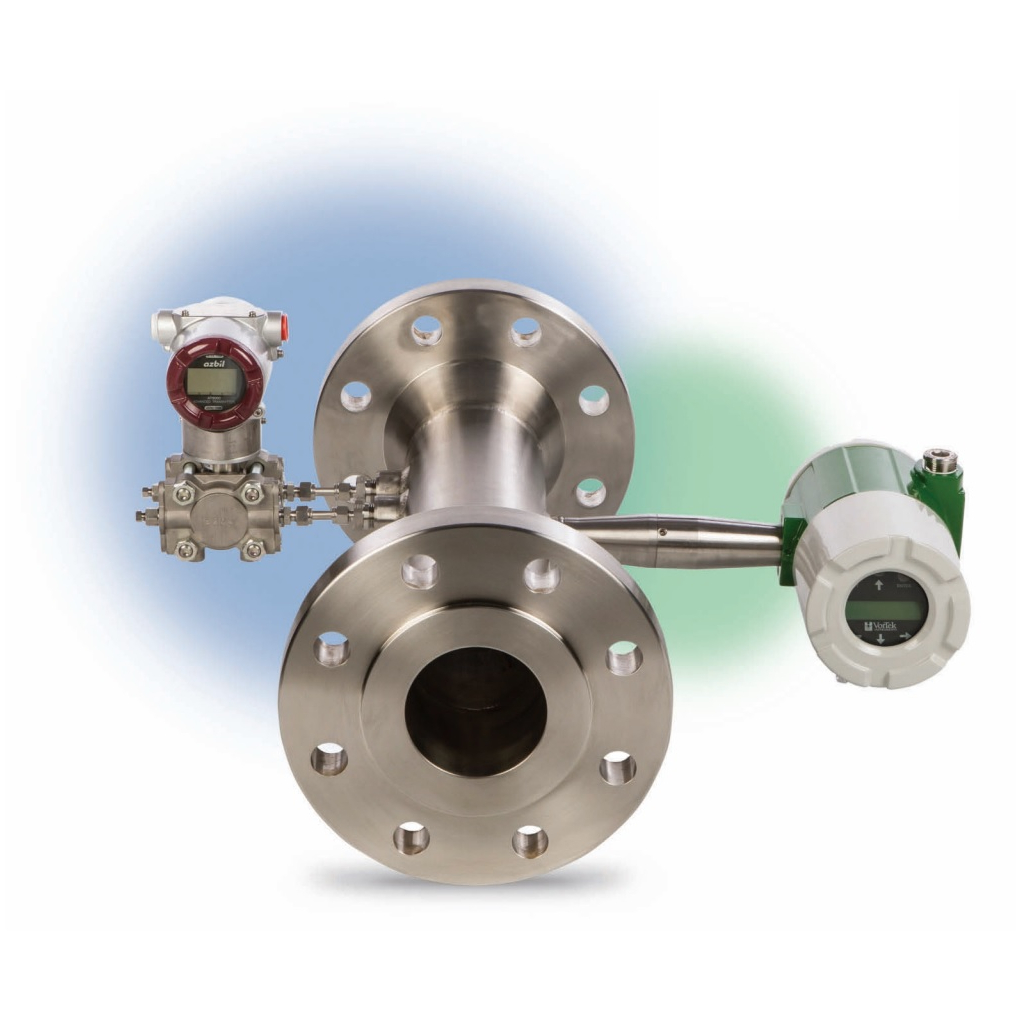

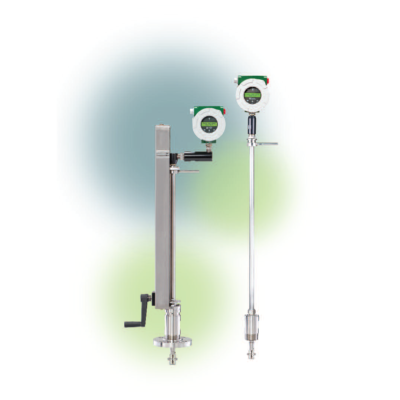

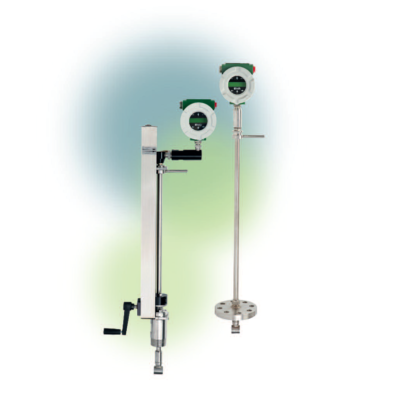

VorTek Instruments’ VorCone™ flowmeters utilize two different flow meter technologies in combination; vortex and differential pressure. The design has blended the two separate flow metering principles into one hybrid system where the two meters complement each other’s performance. This combination allows for the prediction of the fluid density, volumetric flow rate and mass flow rate without any fluid density information being required from an external source.

This ability to measure fluid density allows the meter to provide several valuable outputs. The VorCone meter can calculate the density of changing gas mixtures. For example, natural gas is typically a composition of many different gases which can vary over time and vary by application. In saturated steam service, the meter produces a reliable steam quality (dryness) measurement, and steam mass flow rate reading. In wet natural gas service, the meter is able to provide a reliable liquid loading measurement, and gas mass flow rate reading. These are a few examples of the unique capabilities of the VorCone meter. With the addition of two differential pressure transmitters, advanced diagnostic software (DP Health Check™) continually monitors and verifies the meter’s performance.The VorCone product line is available with a wide range of options and meter configurations to meet your specific application requirements.

Features & Benefits

- Single phase service

- Measures fluid density, volumetric flow rate and mass

flow rate without any density information being

required from an external source - Able to calculate the density of changing gas mixtures.

For example, natural gas is typically a composition of

many different gases which can vary over time and

vary by application - With a VTP model, VorCone is able to compare

calculated density against predicted density to ensure

the accuracy of the density measurement - Energy Monitoring. Ability to compute and output

energy consumption with select fluids. Steam, water,

and heat transfer fluids - Advanced diagnostic software (DP Health Check™),

is able to continually monitor and verify the meter’s

cone element health and confirm output uncertainty

- Measures fluid density, volumetric flow rate and mass

- Saturated steam service

- Provides a total mass flow measurement of steam

and water mixture - Provides a reliable steam quality (dryness) measurement

• More cost effective than current steam quality

(dryness) meters - A combination of the two most proven technologies

for steam metering; vortex and differential pressure

cone metering - Energy Monitoring. Ability to accurately compute

and output energy consumption based on steam

quality (dryness) - With on board data logging, you can track and trend

steam quality (dryness)

- Provides a total mass flow measurement of steam

- Wet gas service

- Provides a reliable liquid loading measurement

- Knowing the liquid loading, the VorCone meter

provides an accurate corrected gas flow measurement - With on board data logging, you can track and trend

liquid loading